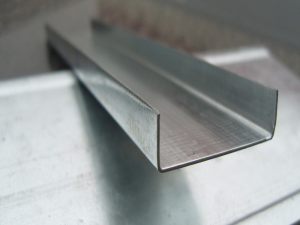

Ibha Eyindilinga Yensimbi Engagqwali

Incazelo

Inqubo yokukhiqiza:

Izakhi ezingahluziwe (C, Fe, Ni, Mn, Cr kanye ne-Cu), ezincibilikisiwe zibe yingothi yi-AOD ecolekileyo, eshisayo igoqwe endaweni emnyama, icoshwe oketshezini olune-asidi, epholishwe ngomshini ngokuzenzakalelayo futhi isikwe ibe yizicucu.

Amazinga:

ASTM A276, A484, A564, A581, A582, EN 10272, JIS4303, JIS G 431, JIS G 4311 kanye ne-JIS G 4318

Ubukhulu:

I-Hot-rolled: Ø5.5 ukuya ku-110mm

Ukubanda: Ø2 ukuya ku-50mm

kwakhiwe: Ø110 kuya ku-500mm

Ubude obujwayelekile: 1000 kuya ku-6000mm

Ukubekezelela: h9&h11

Izici:

Ukubukeka okuhle kwesicwebezelisi somkhiqizo ogoqelwe ngabandayo

Amandla okushisa amahle

Ukusebenza kahle kokuqina (ngemuva kokucubungula okubuthakathaka kazibuthe)

Isixazululo sezwe esingesona i-magnetic

Ifanele ukwakhiwa, ukwakhiwa nezinye izinhlelo zokusebenza

Izicelo:

Inkundla yokwakha, imboni yokwakha imikhumbi

Izinto zokuhlobisa kanye nebhodi lokukhangisa langaphandle

Ibhasi ngaphakathi nangaphandle emaphaketheni kanye nesakhiwo kanye neziphethu

Izandla, i-electroplating kanye ne-electrolyzing pendants kanye nokudla

I-Corrosion- kanye ne-abrasion-free ukuhlangabezana nezidingo ezithile zemishini ehlukahlukene nezinkambu zehadiwe

Ulwazi oluyisisekelo

Izicelo Ezivamile

316 Grade Stainless Steel Round Amabha anohlu olukhulu lwezinhlelo zokusebenza, angasikwa, akheke futhi agotshwe, afakwe imicu, abhobhiswe futhi ashiselwe ukuze asetshenziswe ku:

Izicelo Zasolwandle

Izindawo Zamakhemikhali

Ama-Axels & Shafts

Ama-Grills nama-Grates

Izikrini

Amagridi Okuphepha

Ubunjiniyela Jikelele

Ukulungiswa Kobuso kanye Nezingubo

Ngokungafani nensimbi ethambile ikhemikhali yensimbi engagqwali isho ukuthi izinqubo nezindlela zokuvikela nokuqeda 316 Grade Stainless Steel zihluke kakhulu kuzinsimbi ezithambile.Izingxenye eziningi ezingaphezulu zensimbi engagqwali zizosetshenziswa ngomshini (Ukupholisha) noma ngamakhemikhali (I-Passivating).Indawo efanele yokuqedela izoba nomthelela omkhulu ekusebenzeni nasekubukekeni kwensimbi yakho engagqwali.

Okunye okucatshangelwayo okubaluleke kakhulu ekusebenzeni nokubukeka kweStainless Steels ukuhlanzeka.Indawo engaphezulu idinga ukugcinwa ingenazo izinhlayiya zezinye izinsimbi ikakhulukazi ingxubevange noma izinsimbi zekhabhoni.Ukhuni luphinde lube nezinto ezingcolisa amanzi ezizovuza futhi zingcolise izinsimbi ezingenasici.

Amabanga webha yensimbi engagqwali

| Ibanga | Ibanga | Ingxenye Yekhemikhali % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Okunye | ||

| 301 | 1.431 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | I-Ti5(C+N)~0.70 |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | I-Ti5(C+N)~0.70 |

| 347 | 1.455 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 |

| 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 410 | 1Kr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 420 | 2Kr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 420j2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 430 | 1Kr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - |

| 416 | Y1Cr13 | ≤0.15 | 12.00-14.00 | 3) | ≤1.25 | ≤0.060 | ≥0.15 | - | ≤1.00 | - | - | - |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 |

| 446 | S44600 | ≤0.20 | 23.00-27.00 | 0.75 | ≤1.5 | ≤0.040 | ≤0.030 | 1.50-2,50 | ≤1.00 | - | ≤0.25 | - |

| 431 | 1Cr17Ni2 | ≤0.20 | 15.00-17.00 | 1.50-2,50 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤0.80 | - | - | - |

| 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 |

| 904L | N08904 | ≤0.02 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | ≤0.045 | ≤0.035 | ≤1.00 | 0.1 | Cu:1.0-2.0 | ||